Let me start by saying this printer is a game-changer for anyone needing long or batch prints. The moment I unboxed the IR3 V2, I could tell it was built differently - the custom foam packaging and milled aluminum components screamed premium quality.

The setup was shockingly easy. In just 30 minutes, I had it assembled and printing my first Benchy. No tedious calibration cards or manual adjustments needed thanks to the brilliant auto-leveling system. The Y-offset strain sensor works like magic - just one click and you're ready to print.

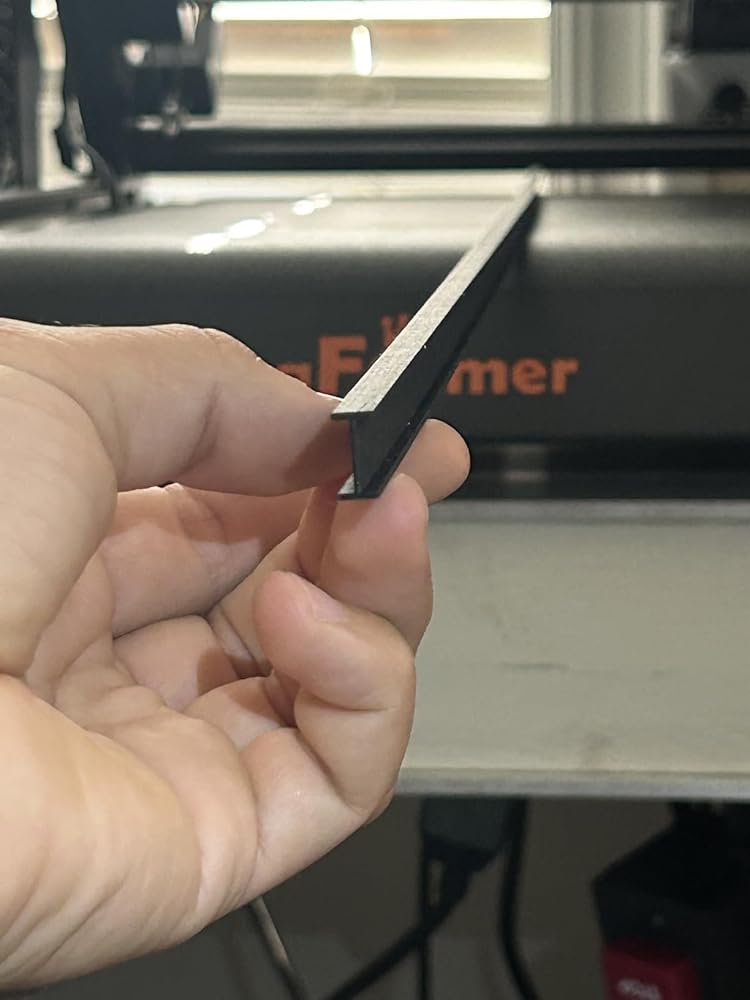

Where this printer truly shines is its infinite Z-axis capability. I printed several 46-inch-long pieces back-to-back without any issues. The metal conveyor belt with PEI coating provides excellent adhesion while being surprisingly durable. Unlike traditional printers where you're constantly removing prints, this just keeps going and going.

The Klipper firmware makes this thing fly at up to 400mm/s while maintaining incredible precision. I was skeptical about speed versus quality, but my test prints came out smooth with excellent layer adhesion using various filaments from PLA to TPU.

My favorite feature? The bed heats up in SECONDS, not minutes. This might seem minor until you've wasted hours of your life waiting for other printers to warm up.

The only minor drawback is the learning curve with the slicer profiles, but even that was simpler than expected. After a couple test prints, I was producing perfect swords and architectural models in single pieces that would normally require complex assembly.

For serious makers who need continuous printing capability, the IR3 V2 is absolutely worth every penny. It's opened up projects I never thought possible with desktop 3D printing.